MIKROTEK MACHINES LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to MIKROTEK MACHINES LTD.

Natural Diamond Dies

Description / Specification of Natural Diamond Dies

We are involved in offering a wide range of Natural Diamond Dies to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Natural Diamond Dies. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

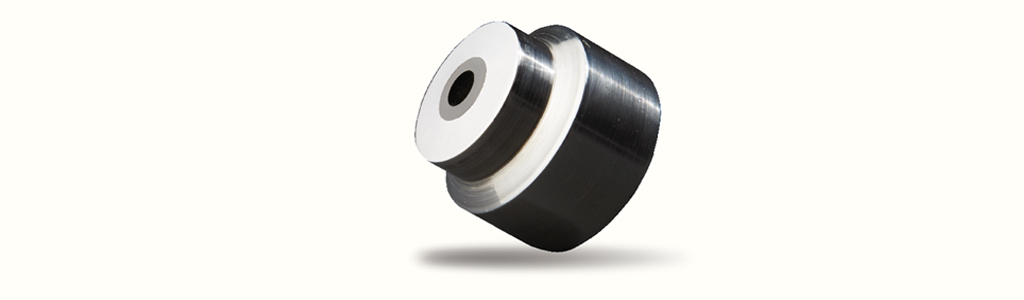

Polycrystalline Dies

Description / Specification of Polycrystalline Dies

We are involved in offering a wide range of Polycrystalline Dies to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Polycrystalline Dies. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Mono Diamond Dies

We Manufacture Mono diamond dies in the size range of 0.015 - 1.2 mm.

These Mono diamonds are man-made diamonds which are also called as Synthetic Single Crystal Diamond (SSCD).

Mono dies are manufactured by using the raw materials purchased from M/s Element Six & M/s Sumitomo.

Our Mono dies are widely used for drawing Stainless Steel, Copper, Aluminium, EDM, Tungsten, Molybdenum, Medical, Gold, Silver and Alloy wires etc.,

Tc Drawing Dies And Taper Inserts

We offer Tungsten carbide dies in the size range from 0.200 to 30 mm for wire, rod, bar & tube drawing. We use the best quality of tungsten carbide nibs purchased from reputed companies for various drawing applications. Our high speed state of the art equipment ensures that each die is perfectly ground, concentric and mirror polished. Our strict quality control ensures accurate angles, bearing length & close tolerances on bore dimensions. Also, we can customize these products as per the specifications provided by our esteemed clients.

Solid Enameling Dies

We manufacture Solid enameling dies with Diamond insert from 0.200 to 6. 00 mm.

Perfect inner profile allows smooth and continuous flow of enamel on the copper wire and ensures uniform coating. Mikrotek offers standard and customised design in both Stainless Steel and Aluminum bodies.

Monocular Microscope Mtcm

Description / Specification of Monocular Microscope Mtcm

We are involved in offering a wide range of Monocular Microscope Mtcm to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Monocular Microscope Mtcm. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

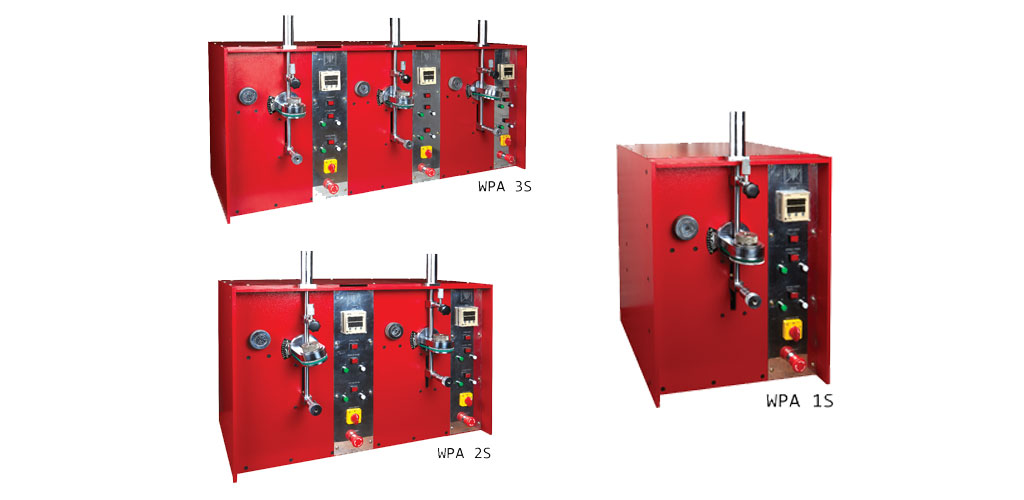

Wire Polishing Machine

The machine is manufactured with precision engineering and especially consists of self cantering type oscillating die holder and reciprocating wire clamping device. Die rotation and stroke speeds are continuously variable. All operations are controlled by electronic timer with digital display. Spindle and stroke motors are controlled through AC drives.

Vertical T C Die Working

The machine is designed and developed for working of reduction and bearing portion of the Tungsten carbide dies. Also the machine can be used for working special tools, extruder dies, round bores of hard metals etc.

The machine consists of a high speed grinding spindle and a die table. The needle fixing is by collet arrangement. A precision 3 jaw chuck is used to hold the dies. The spindle stroke, stroke length and the die speed can be varied.

The machine works on a special principle wherein both the reduction and bearing zones of the die can be worked in one setting there by producing the concentric dies.

Horizontal Tc Die Working

Description / Specification of Horizontal Tc Die Working

We are involved in offering a wide range of Horizontal Tc Die Working to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Horizontal Tc Die Working. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Tc Die Bearing And Sizing Machine

Description / Specification of Tc Die Bearing And Sizing Machine

We are involved in offering a wide range of Tc Die Bearing And Sizing Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Tc Die Bearing And Sizing Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Needle Grinder

The Grinder is designed and developed for grinding accurate angles with 0.5 degrees on hardened steel and special wooden needles. The Machine mainly consists of a grinding wheel and reciprocating needle holding device. This grinder is used in combination with TC & Diamond die working equipment to achieve accurate die angles.

Bunching Stranding And Compacting Die

We are offering Compacting Die to our valuable clients. We use superior quality raw material and latest technology to manufacture these products. Also, we can customize these products as per the specifications provided by our esteemed clients.

We manufacture compacting dies using both PCD & TC. In PCD dies, we manufacture upto 32 mm and in TC dies upto 50 mm.

Mikrotek compacting dies are precisely manufactured to assure right profile, well polished trumpet entry to avoid wire scraping, well polished cone angle and bearing length for proper compacting of wires and longer die life.

Diamond Angle Pins

Diamond Plated Angle Pins are used for grinding of Tungsten carbide dies. We use specially treated diamond grits, which are electro plated to the shank of the pin. More no of grit faces or cutting edges results in sharp cutting, less clogging and better grinding efficiency. These pins are available in conical shape with cylindrical shaft.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.